Description

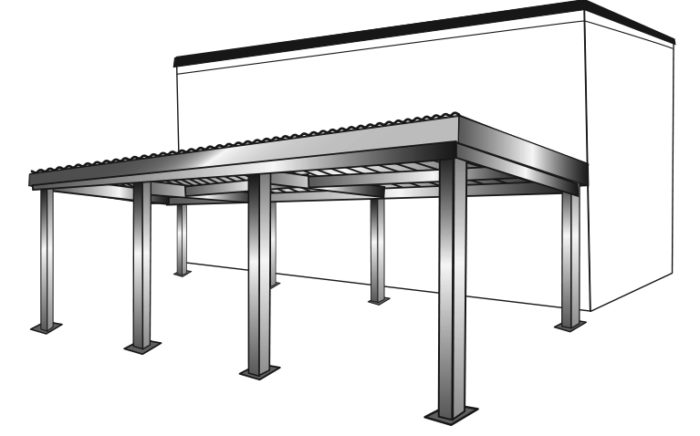

Industrial Structure Solutions Canopies

A canopy with a galvanized ceiling is perfect for outdoor applications. These canopies can withstand the environment, with structural capacities sustaining live loads of 20 pounds per square foot and wind loads up to 70 mph. Dimensions for Industrial Structure Solutions Canopies are also customizable. They typically have roof slopes of 3/8” to 12” and are constructed with 1/2” thick, 12” square base plates, fastened with wedge anchors. They provide strength while allowing for design flexibility.

Industrial Structure Solutions Brochure Platforms and Mezzanines

Industrial Structure Solutions Brochure Free Standing Mezzanines

Framing elements are cold formed, with a G60-coating and Grade D, ASTM A446 high tensile steel. This means high strength-retention—50,000 PSI minimum yield—and as much as a third less weight than typical steel structuring, making them an economic solution. A signature feature of Industrial Structure Solutions Canopies is the integrated galvanized or painted finish, which lends a sharp professional look and also resists scratches and corrosion.

Framing Types:

- Beams: “C” and “Z” shape beams, normally 10 and 12 gauge, in sizes 12”, 16” and 20” and fastened with non-galvanized, 3/4” heavy duty ASTM A490 bolts.

- Square columns: 9” square columns with a welded 14” x 14” x 1/2” minimum baseplate, held with four 3/4” wedge or epoxy anchors. Be sure to check local requirements for embedment and type.

- Joists: “C” shape joists, normally 10, 12 or 14 gauge, sizes 8”, 10”, 12”, 14” and 20”, connected with 5/8” bolts and “L” shaped clips.

- Struts: “C” shape struts, 10 and 12 gauge, in sizes 12”,16” and 20”, connected with heavy-duty ASTM A490 bolts.

Decking also comes in an impressive line of options, from wood, diamond plate, open grating and more. Engineered wood products are typically Deck-Pak and Resin Deck. Diamond Plate adds drop resilience when combined with engineered wood product. Workmanship and materials come with a full warranty.

Decking Types:

- Wood on B-Deck: 1-1/2”, 18, 20 or 22 gauge B-Deck (galvanized corrugated roof-decking) with a 3/4” or 1-1/8” wood product overlay. B-Deck is required for walking as it provides the load-bearing strength. Surfaces are secured with #9 x 2” bugle head tek screws and #12 x 3/4″ tek screws.

- Plank Pak: a 2” x 9” galvanized nonskid surface created by holes in embossed dimples for traction. Held with #12 x 3/4” tek screws and j-bolts/clips.

- Diamond Plate: painted, galvanized or plain, 1/4”, 3/16” or 1/8”, on 1-1/2” B-Deck. Fastened with #8-32 x 1” truss head screws and #12 x 3/4 tek screws.

- Concrete: form decking, held with #12 x 3/4” tek screws, that is later filled with concrete.