Description

Full and Split-Roller Designed by Seasoned Manufacturer

Full and Split-Roller by Mallard Manufacturing is the world’s premiere producer of pallet rack integrated conveyor systems. Family owned since 1960, Mallard has been a material handling industry leader for pallet flow racking, carton flow rack and gravity flow conveyor systems since it’s inception. Their Full and Split Roller Pallet Flow Racking are flexible, durable solutions to the ever-changing list of challenges presented to warehousing, logistics and distribution companies.

Maximum Flexibility for Every Type of Pallet

Mallard’s Full Roller Pallet Flow systems consist of sets of galvanized metal rollers that span the width of flow lanes up to 60”, integrated into standard pallet racking. Highly flexible and adaptable, Full Roller systems are ideal for plastic and odd sized pallets of any size and shape. Custom mounting brackets provide options for secure, low-profile, or heavy-duty use cases. The supporting structure can be either welded or bolted using most major manufacturer’s pallet rack components for maximum flexibility and lower costs. Support beams are placed at the appropriate heights within the racking to maintain proper gravity fed pallet flow, while optional pallet flow speed controllers regulate the speed of the pallets as they move down the flow rails.

Heavy-Duty Pallet Flow for the Toughest Jobs

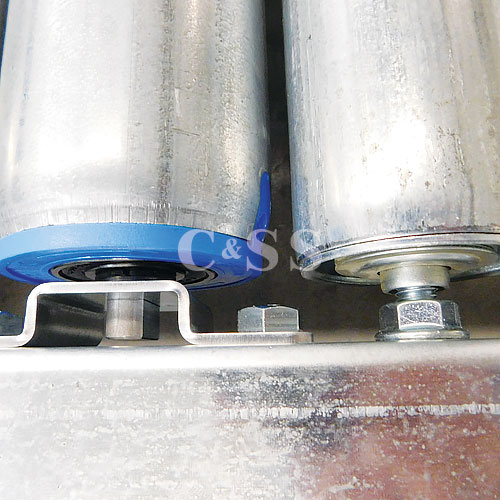

Mallard’s Split Roller Pallet Flow systems consist of at least two sets of galvanized metal rollers designed to fit specifically dimensioned heavy-weight pallets. Heavier pallets can cause minor deflection in full width rollers which could negatively impact flow. Split-roller systems are also ideal for extra-wide, unwieldy loads. The number and spacing of flow rails are always dependent on the dimensions and weight of the loads. As with the Full Roller Pallet Flow systems, a variety of custom mounting brackets are available, offering the ability to integrate into most standard roll formed or structural pallet racking.

Easy to Service for Long Life

While Mallard’s Full and Split Roller Pallet Flow Rack designs are engineered and built to the highest standards using heavy-duty components, even the toughest designs can become damaged by extra hard use or abuse. As such, both are designed with maintenance in mind, so if damage occurs, replacement components like bearings, axles, tubes, and side channels can easily be installed. This keeps your warehouse streamlined and flowing, cutting down on costly interruptions.

Custom Designed to Suit Every Project

Custom designed to suit a variety of applications, Full and Split Pallet flow systems are constructed with rollers available in both 1.9” and 2.5” diameters. Lanes can stretch from 4” up to 60”, with capacities from 260 Lbs. to 350 Lbs. per roller. Accessories like speed controllers, ramp stops, and entry guides are available as needed. Mallard’s in-house engineers work in concert with trusted distributors like Conveyor & Storage Solutions to make sure every design is perfectly suited to its task.

Determining if a pallet flow system is the right choice for your warehouse or business need not be complicated. They are excellent at the heart of FIFO systems, offering high density without the need for automation. They enable the maximization of smaller warehouse footprints, meaning the most money per square foot a warehouse can produce. Cold storage facilities like food and beverage distribution also stand to greatly benefit from the streamlining capabilities of pallet flow. However, the easiest way to decide if pallet flow is right for you is to give the experts over at Conveyor & Storage Solutions a consultation call today!